What Is A Welded Diff?

So, for someone who is into drifting, they all understand well the purpose of a welded differential. But anyone who never ever drifts, welded diff is something really difficult. So let us introduce to you what is welded diff and how to weld a diff.

What Is Welded Diff?

In short, welded diff allows for both the back wheels to remain spinning at the same speed. In deep, there is more to know than it. We will give you a deeper explanation about welded diff and what does a welded diff do.

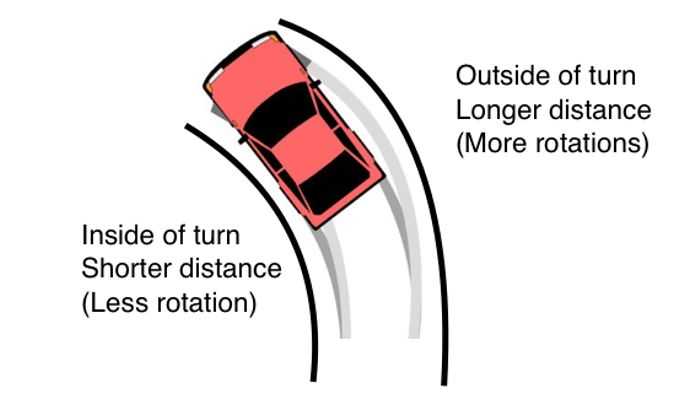

Let’s start from a normal differential, the wheel on the inside of the turn has to rotate less than the wheel on the outside. Since the wheel on the outside has a further distance to go, as it is on the long far side of the car from the corner. And bottom line, the outside wheel needs more revolutions than the inside wheel.

So after you weld the diff, the axels are almost strung together and both wheels will rotate the same revolutions as each other. Now, the wheel spins at the same speed through a corner. It forces the inner wheel to spin at the same amount of the outer wheel. The inner wheel skips across the ground as if it were playing a game of hopscotch.By that the car with welded diff will drive very differently than most cars on the road.

Welding a diff may cause many serious problems and will wear the tires out quicker than usual. So you should carefully consider before deciding whether to weld a diff or not. Let’s look at the consequences of welding a diff!

What Could Happen If You Weld A Diff?

Pros of Welded Diff

The most common pros of welding a diff is keeping both the back wheels on the car spinning faster than the inner wheel in a turn or corner. As you know, keeping both the wheels spinning at the same rate will cause the inner wheel to lo0se traction and skip, making oversteer easier to accomplish. So welded diff can prevent it.

Moreover, welded differential vs limited slip is far cheaper and allows you to drift more easily. You can still easily drift with an LSD diff but most will only lock up under a certain amount of torque, which can be difficult in low powered cars.

SEE MORE:

- Bad Differential Symptoms And Repair Cost Estimation

- How To Weld Metal Sheet? The Process

- How To Remove A Broken Bolt Without Losing Your Mind

Cons of Welded Diff

Besides that, the cons of welding a diff are serious if you do not pay attention to what you are going to do. First of all, if you do it in the wrong way, you will turn it into a shrapnel grenade which will definitely not be a good thing.

Secondly, welding a diff will make the car more difficult to turn means slow, tight corners will be sucked. You will see if you are going to be doing a lot of tight parking and reversing, a welded differential may be a major pain to your body. Moreover, the car parts will be damaged if you did something wrong to the differential.

It’s what you should keep in mind before going to weld a diff. If you are sure about what you are going to do. Do not hesitate to follow our steps of how to weld a differential. It will help you weld a diff in the correct way to make sure you will not ruin your car.

How To Weld A Diff?

Step 1: Removing the Differential from The Car

It is the very first step you should do in order to make welded diff. If you are new to welding a diff, it is advised that you purchase a used differential in case anything goes wrong. Or maybe you want to return it back to an open differential.

Step 2: Draining the Oil and Remove the Housing

After you remove the diff from the car, the next step is draining any oil and removing the housing. Make sure that you already clean the diff since the little bit of tough bits of dirt can harm your whole process. You can use the brake cleaner to do it.

Step 3: Welding the Differential

So you already remove the diff from the car, the process of draining oil and taking away the housing is completed. Now, time for welding the diff. The most effective way to do it is start from the corners where the spider gears meet together. By doing that, more steel is connected and making it a more solid weld. Someone else just simply weld the diff where the gears meet and that is the weld complete.

Step 4: Cleaning Up

The last step of welding is cleaning up before installing the diff back into your car. There is nothing that should appear inside the diff only when you want to let them in. So cleaning and making sure there is no dirt inside.

Sum Up

These four steps on how to weld a diff are easy to follow and the result is effective. Beside the benefit of welded diff such as keeping both the back wheels on the car spinning faster than the inner wheel in a turn or corner. There is a chance that your car will be damaged a lot. So as we recommended, consider the benefits and drawbacks of welded diff before going to do it.

Moreover, check out other maintenance tips to know more about your car problem, how to diagnose and the way to fix it. If you have any questions, do not hesitate to leave a comment, we will be back and support you.